The Delta Labs Super Timeline ADM2048 is quite possibly the most interesting circuit I’ve worked on so far. I’ve always wondered how an old-school digital delay works, and this late ’80s digital IC-based technology allowed the opportunity to reverse engineer the general concept.

This particular unit showed up without the ability to power up. In this article, we take a dive into what went wrong and how we made it right.

As a member of the Reverb Partner Program and as an Amazon Associate, StompboxElectronics earns from, and is supported by, qualifying purchases.

Disclaimer: Stompbox Electronics and/or the author of this article is/are not responsible for any mishaps that occur as a result of applying this content.

Delta Labs Super Timeline Not Working

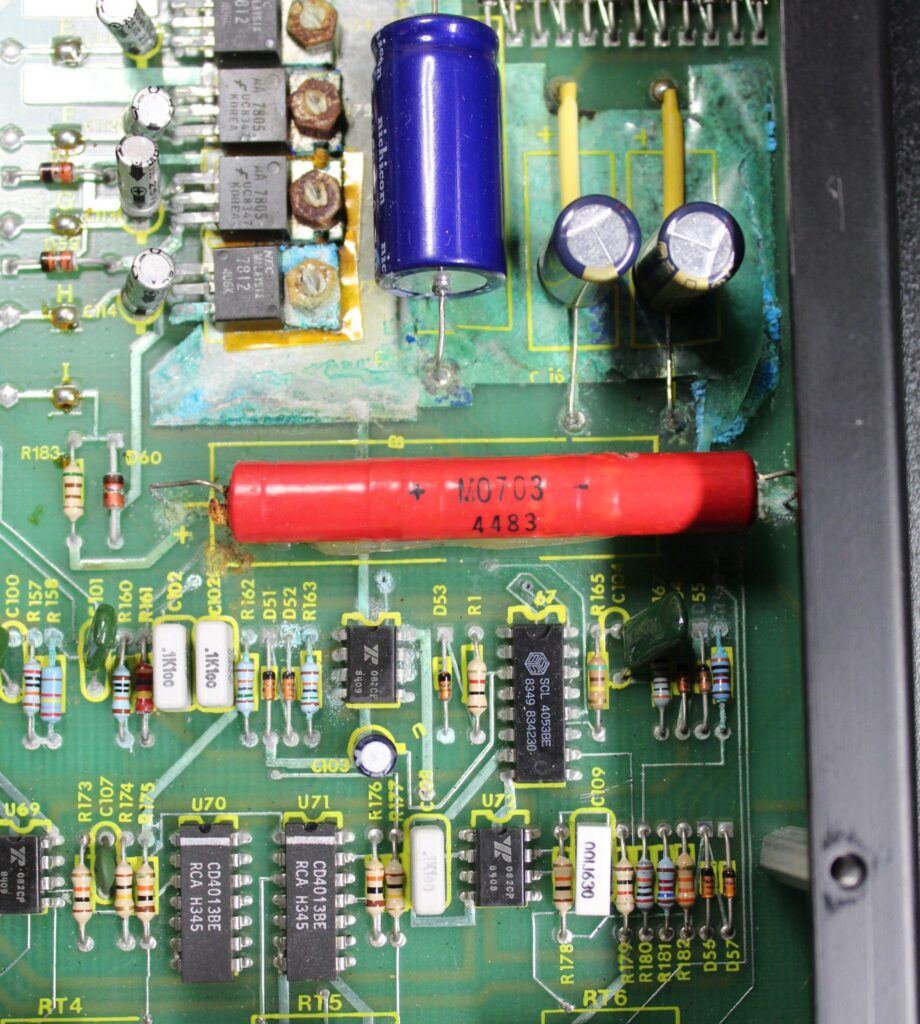

When I received the Delta Labs Super Timeline it was completely dead. No lights, no nothing. On opening the unit I immediately noticed why: the battery had bursted! As a result, there was a corrosive compound found all around where the battery sits. The fuse also had to be replaced, this thing was a real piece of work.

Super Timeline Repair Troubleshooting

The first thing I did was snip the battery out of the circuit and replace the blown fuse. After powering it up, lights came on and it was operational. Considering how the inside of the unit looked, it was a great surprise that a simple fuse replacement got it at least operational again!

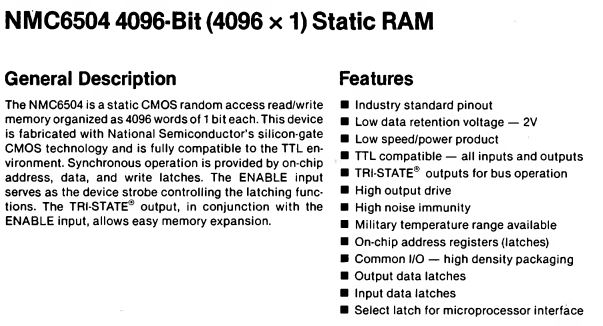

Playing with the functions a bit, I noticed the entire presets section of the circuit wasn’t working. There is an SRAM chip (NMC6504) responsible for storing the 4 preset configurations: Presets A, B, C, and D. SRAM chips need constant power in order to maintain the stored information. For this reason, the NMC6504 was originally powered by the battery. With that battery gone, no power could get to the chip and no presets were able to saved or recalled.

Replacing the Delta Labs Super Timeline Battery

Now that I knew what the general problems were, it was time to source a battery replacement. There were no specifications on this battery model found online, and so no direct replacement (sad face). So, digging into layers of forums, I eventually found a schematic.

With the schematic in hand, I was able to determine that the stock battery voltage is 4.6V, and the test point for the battery voltage is labeled +5VB after the zener. After some more searching for suitable battery replacements, I settled on a Varta 4.8V NiMH from JLS Batteries on eBay (paid link). It was similar to this Varta 4.8V model, also currently on eBay.

That Varta battery was a through-hole component, but it didn’t match the footprint of the original battery. So, I soldered wires from the + and – sides to the appropriate vias.

To secure the wiring to the battery’s body I used electrical tape and twisted the wires together to provide additional support. The electrical tape may also help in preventing a large amount of damage to occur in the case that this NiMH fails in the future. A square piece of Velcro I got from Amazon was used to secure the battery to the main board.

As an Amazon Associate, Stompbox Electronics earns from, and is supported by, qualifying purchases.

Why a NiMH?

Since the schematic didn’t specify the battery type, the choice of a NiMH was based on the color of the corrosion that occurred on the copper traces and component leads. NiMH batteries contain the hydroxide anion (OH-). In the presence of an electrical current and physical contact, the hydroxide anion and copper can react to form copper (II) hydroxide, which is blue in color.

This reaction is corrosive and literally eats away the copper traces on the board. If enough corrosion takes place the board can become irreparable! Or at least extremely hard to repair without re-engineering and rebuilding the circuit. Luckily, that didn’t happen here.

Final Steps for the Delta Labs Super Timeline Repair

Once the replacement battery was installed I powered up the Super Timeline and presets were operational!

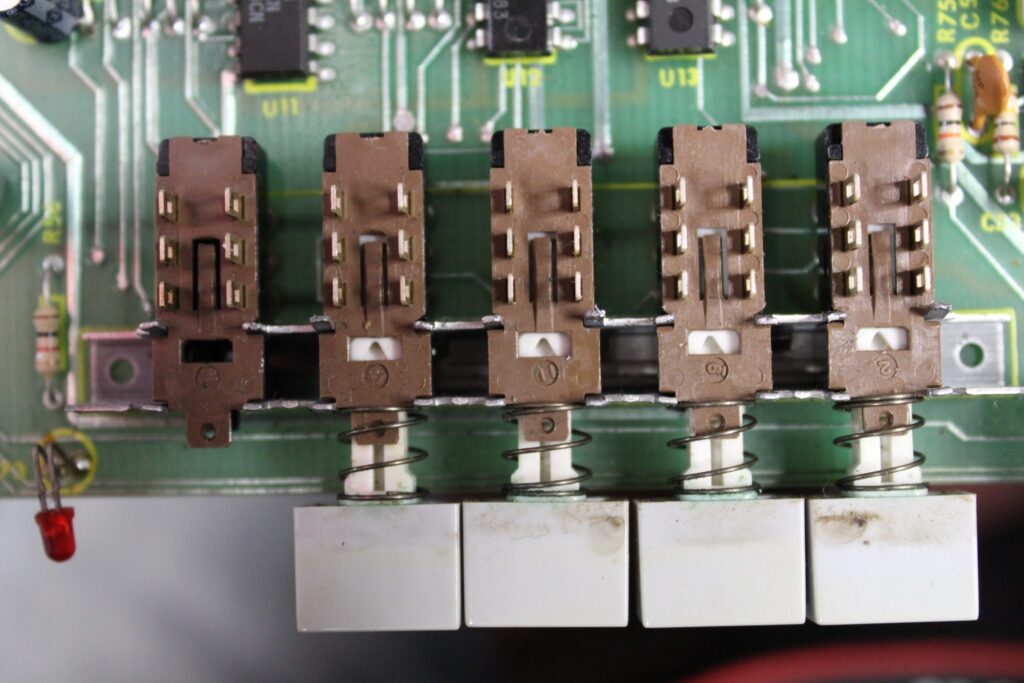

The contacts for the presets, however, were extremely unreliable. They would make contact maybe 60% of the time, so I ended up removing all of the preset buttons and their switching actuators. I tinned a thin, even layer of solder onto each contact and reinstalled them; that ended up working very well.

Cleaning the Circuit Board

After tinning the preset contacts I took aim to the copper (II) hydroxide build-up near the power and LFO circuits. I cleaned a toothbrush with distilled water, then started brushing the corrosion build-up off the leads. While cleaning with the toothbrush, I noticed that the component labeling was getting scraped off (as if they were old stickers). From that point on I was very careful in removing the corrosive material and mainly focused on relatively open areas between components.

It’s not perfectly cleaned, but the unit was working and I didn’t want to ruin the labeling scheme, as it may prove useful down the road. If anybody has an abrasive-free solution for cleaning copper (II) hydroxide from PCBs I’d be highly interested!

Lastly, to remove the distilled water I used some combination of paper towels, a hair dryer, and an air compressor.

Meet the Author:

Hi, I’m Dominic. By day, I’m an engineer. By night, I repair and modify guitar effects! Since 2017, I’ve been independently modifying and repairing guitar effects and audio equipment under Mimmotronics Effects in Western New York. After coming out with a series of guitar effects development boards, I decided the next step is to support that community through content on what I’ve learned through the years. Writing about electronics gives me great joy, particularly because I love seeing what others do with the knowledge they gain about guitar effects and audio circuits. Feel free to reach out using the contact form!

Spotlight

This fix was done for DMS Productions located in Ransomville, NY!

The Tools I Use

As a member of Amazon Associates, Stompbox Electronics earns and is supported by qualifying purchases.