I recently got my hands on a dead TC Electronic Finalizer 96K Studio Mastering Processor from DMS Productions in Ransomville, NY. It won’t power up, no lights, no sound, no nothing. Right off the bat this sounds like a power supply problem!

As a member of the Reverb Partner Program and as an Amazon Associate, StompboxElectronics earns from, and is supported by, qualifying purchases.

Disclaimer: Stompbox Electronics and/or the author of this article is/are not responsible for any mishaps that occur as a result of applying this content.

The Breakdown

Five screws hold down the top panel. Upon opening and inspecting the unit there are two main boards – the power supply unit and the main processing board.

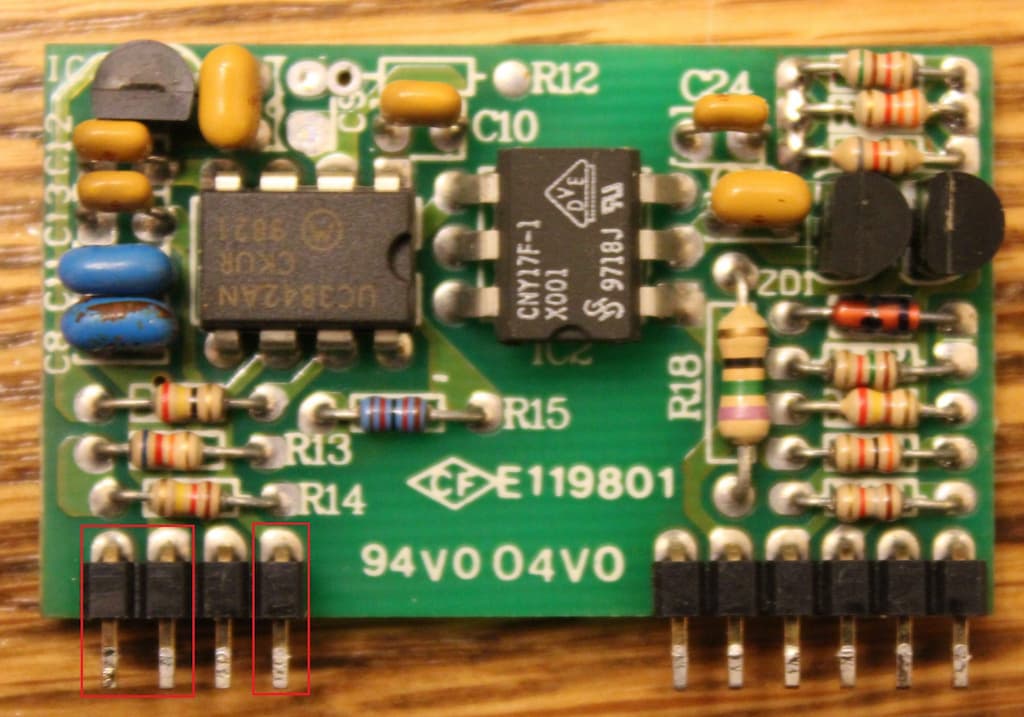

The vertically-mounted daughter-board sitting next to the transformer houses a switch-mode power supply (SMPS). SMPS’s use a pulse-width modulation (PWM) switching controller (also mounted on the daughter-board). The current-mode Texas Instruments TL3842BP is the PWM controller of choice – also mounted on the daughter-board.

The output of the PWM controller is fed into a TL431 Programmable Voltage Reference. Due to the TO-92 package it seemed like a transistor at first glance. The voltage reference from the TL431 is routed to other areas of the power supply circuit, converted to other DC voltages, and cleaned through some passive filtering.

Visual inspection reveals some corrosion on a capacitor and resistor sitting next to the daughter-board. Also, other caps near the output power sources had the same amount of corrosion.

Before electrical troubleshooting I thought it may be best to first search the forums on issues with this unit…boy were there issues! I’m grateful that Svart from GroupDIY was generous enough to post his fix in a thread describing almost this exact problem. He describes a bad electrolytic cap (100uF, rated 25V) next to the daughter-board being the cause of his issue.

That’s the same cap I found corroded on this unit! Immediately this capacitor was on the replacement list. To be safe, I also added the 1.2Mohm carbon resistor sitting next to it. Some other 82uF electrolytic caps near the output wiring also made the list.

The Troubleshooting

Having a list of the voltages carried on the output wires, along with the labels of said voltages on the main board, I was ready to troubleshoot the board. I read zero volts on every rail against the proper ground/reference wires. The output was in fact dead.

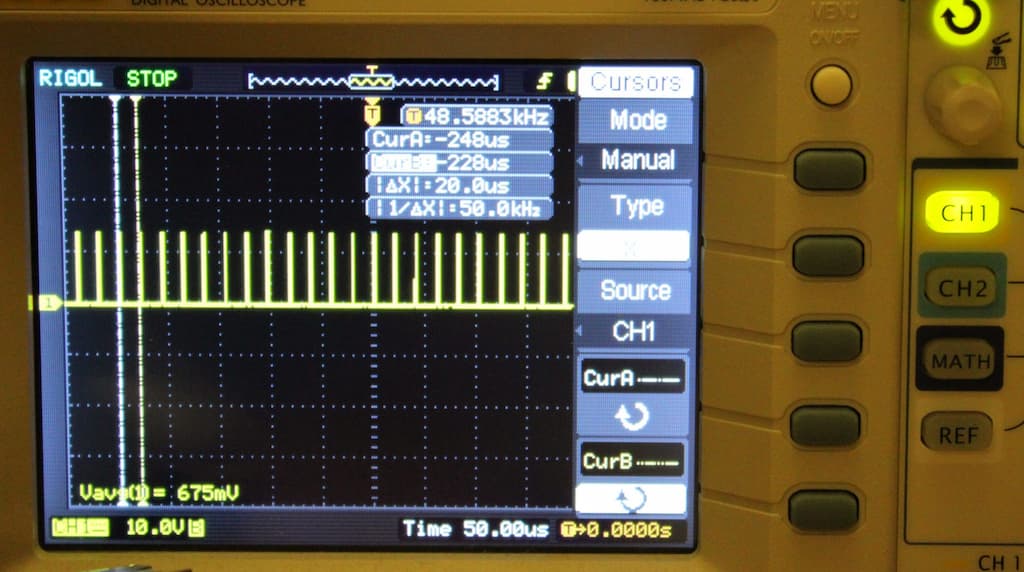

I turned to the PWM board and found out the output of the controller chip is pin 6. Measuring that on the oscilloscope revealed the chip wasn’t properly producing its PWM signal.

I also measured the Vcc power input for the PWM chip, which revealed about 14.36V. This particular controller has a minimum start-up supply voltage ranging between 14.5-17.5V. I believed this voltage was not being reached due to the damaged cap and resistor on the supply line to the PWM chip.

The Repair

After replacing the caps and resistor I tested the output lines for proper voltages. The +15V and -15V rails were reading about +16V and -16V, respectively, which I was okay with. The only other DC voltage I was able to measure was the 6V line. The 5V lines were not readable, which was confusing to me.

After some more research I found out it was a normal problem. There is apparently a “handshake” signal (carried by the brown wire) between the power supply and main board for activating the 5V line.

Even with that bit of advice, I still wasn’t sure if it was working. I hooked up the oscilloscope and found the PWM controller’s output pin to be operational at about 50kHz frequency. With that reassurance, I connected the supply to the main board and the Finalizer arose from the dead!

Wrap-Up

This was a fun one for sure! It’s evident that this issue isn’t the fault of the consumer. The same issue has occurred on multiple units. There must be a design flaw in the supply – maybe improper filtering, under-rated components, missed safeguards, etc. It’d be a tremendous move by TC to provide replacements for these power supply units to independent repair techs. See Right to Repair 🔧

Meet the Author:

Hi, I’m Dominic. By day, I’m an engineer. By night, I repair and modify guitar effects! Since 2017, I’ve been independently modifying and repairing guitar effects and audio equipment under Mimmotronics Effects in Western New York. After coming out with a series of guitar effects development boards, I decided the next step is to support that community through content on what I’ve learned through the years. Writing about electronics gives me great joy, particularly because I love seeing what others do with the knowledge they gain about guitar effects and audio circuits. Feel free to reach out using the contact form!

The Tools I Use

As a member of Amazon Associates, Stompbox Electronics earns and is supported by qualifying purchases.